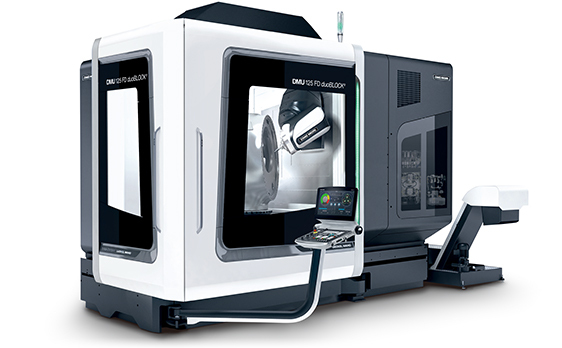

Dmg Mori Dmc 80 Fd Duoblock

MAINTENANCE KIT DMC 80 FD DUOBLOCK

Our maintenance kits have been individually compiled for your machine tool and exclusively contain original DMG MORI spare parts.

CONTAINS

Does imgburn support dmg files. After theburning completes, you should see the message, 'Burning completedsuccessfully'. If the disc is rewritable andnot empty, anyburn will prompt you to erase the disc automatically beforeburning.AnyBurn will show the progress information during burning. AnyBurn will start burning DMG file to the disc.

DMC 125 U duoBLOCK - 5 Axis CNC Milling Machines and 5 Axis CNC Milling Centers by DMG MORI. 5 Axis Milling. DMC duoBLOCK Series. DMC 125 U duoBLOCK. DMC 125 FD Grinding. Application Examples. Standard automation and customised solutions in the VERTICO design.

- Wiper set f. steel cover Y-Axis

- Wiper set f. steel cover pallet change

- Wipers for cabin

- Filter elements f. pneumatic/hydraulic

- Filtermat(s) for cooling unit(s)

- Low viscosity grease 900gr

- Turmogrease 400gr for FD-bearing

- Sealing kit for clamping set

Further maintenance / spare parts for additional or special options from your regional sales and service company on request. Scope of delivery may differ from the illustration.

Complete machining

- Milling and turning in one setup with the DirectDrive table and rotational speeds up to 500 rpm

- Best surface quality with technology integration grinding

Dmg Mori Dmc 80 Fd Duoblock Price

Precision

- Maximum accuracy through completely water-cooled feed drive

- SGS: Spindle Growth Sensor for Compensation of spindle increase

- Significantly improved temperature response

Performance

- Fast, very compact rotating pallet changer for main time parallel setup as standard

- Also available in mill- /turn - version

- powerMASTER motorspindle with 1,000 Nm and 77 kW

- 5X torqueMASTER with 1,800 Nm and 52 kW

Efficiency

Dmc 80 Thread

- Low space requirements, extremely compact wheel magazine with short tool replenishment time of max. 5.6 sec with 453 tool pockets

- Optimal ease of maintenance and ideal ergonomics thanks to unrestricted accessibility

- High machine availability with 95 %